Inventory Management for Indian Dropshippers: Stop Bleeding Orders & Start Scaling Smooth (2025 Guide)

Discover the ultimate guide to inventory management for Indian dropshippers in 2025. Learn how to stop stockouts, improve backend ops, and scale profitably with real Indian ecom context.

Table Of Content

- 1. Start with a Clear SKU System

- 2. Use a Shared Sheet (Seriously, No Excuses)

- 3. Set Low-Stock Alerts (Your Backup Brain)

- 4. Always Have a Reorder Plan (Not Just Hope)

- 5. Weekly Inventory Check (Not Daily, Not Random)

- 6. Use Tools When Spreadsheets Start Breaking

- 7. Plan Around Indian Seasonality (And Not Last Minute)

- 8. Don’t Overbuy to Feel Safe

- 9. How to Handle Inventory When You’re Scaling Fast

- ✅ Switch from solo to team mode

- ✅ Outsource your fulfillment (if needed)

- ✅ Automate reorder workflows

- ✅ Set inventory KPIs

- ✅ Forecast like a grown brand

- Final Word on Inventory Management Basics for Indian Dropshippers

Let’s keep it real — nobody wakes up pumped to manage inventory. But if your backend’s messy, your business won’t just slow down… it’ll collapse silently while you’re busy fixing ads.

Think about it:

- Ads start popping? You’re out of stock.

- Courier asks for pickup? Product’s in some random drawer.

- Customer gets the wrong color? And now they’ve left a 1-star review.

That’s not a marketing problem, bro. That’s you not having your inventory sorted.

In Indian dropshipping, where COD, RTO, shipping delays, and impatient customers are normal — your backend systems can’t be vibes. They have to be sharp.

This guide is for dropshippers who are done with chaos and want to:

- Keep things lean but efficient

- Avoid dumb mistakes that cost real money

- Fulfill on time without playing guessing games

- And finally scale without feeling like you’re putting out fires all day

No guru theory. Just what works in real Indian dropshipping in 2025. Let’s get into inventory management for Indian dropshippers — the real version.

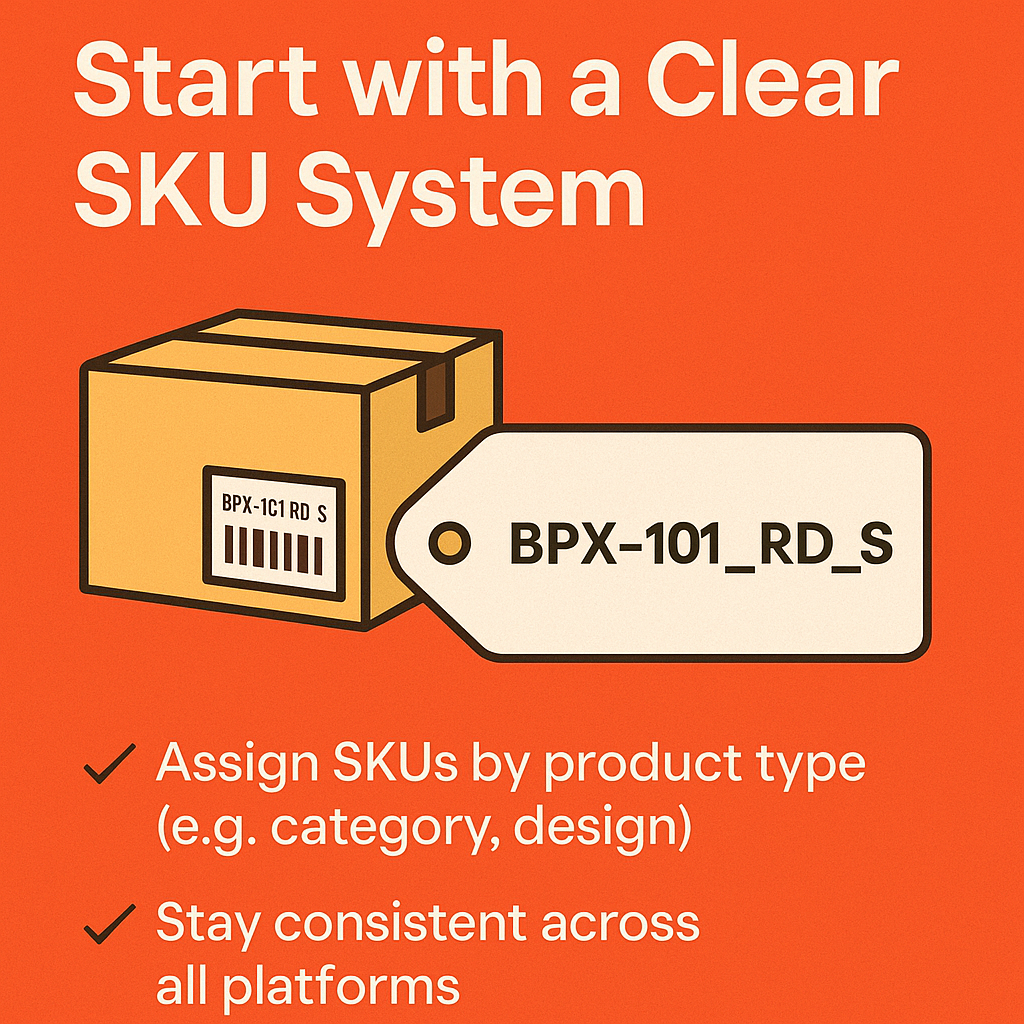

1. Start with a Clear SKU System

Stop naming your product “Black T-shirt 1” or “Kurti B.” That’s not an SKU — that’s confusion waiting to happen. Poor naming leads to mix-ups, wasted time, and frustrated packers. When you’re processing hundreds of orders a week, every second counts.

There is need of clear, structured SKUs that speak in 3 seconds or less for an Inventory Management for Indian Dropshippers:. For example:

- HOD-BLK-M = Hoodie, Black, Medium

- KRT-RD-L = Kurti, Red, Large

These short, smart codes tell your warehouse or packing staff exactly what to pick — no questions asked. No “wait, which black T-shirt?” No back and forth. Just fast, efficient order fulfillment.

And it doesn’t stop there. Well-structured SKUs make inventory tracking easier, reduce packing errors, and make the return process smoother and faster. Whether you’re managing stock manually or using software, SKUs act as the language of your inventory — and every team member should be fluent.

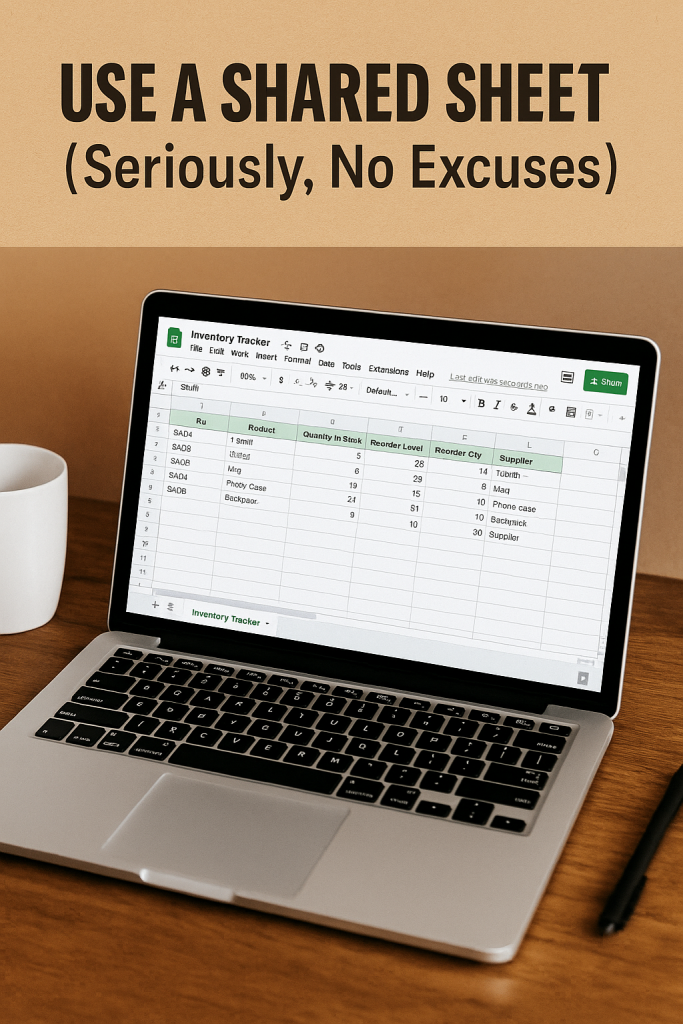

2. Use a Shared Sheet (Seriously, No Excuses)

This one’s basic, but so many skip it. If you’re packing from home, and you’re not tracking live stock in a Google Sheet — you’re already slipping.

You need real-time clarity, even if you’re a one-man army. That Google Sheet is the mission control for Inventory Management for Indian Dropshippers: . When you or someone else touches inventory, it gets logged instantly — no excuses, no memory games.

Track the essentials:

- SKU

- Product name

- Current quantity

- Storage location (shelf, box, kitchen drawer — whatever)

- Minimum reorder level

- Last updated by (just add initials)

- Remarks or damage notes

Why this matters? Because when 3 things sell in one hour and your packer doesn’t update the sheet, you’re flying blind the next day. And that’s how refund loops and angry calls start.

Pro tip: Color code the sheet.

- Green = in stock

- Yellow = low stock

- Red = reorder now

Even better? Use conditional formatting to auto-highlight low quantities.

Also — back this sheet up weekly. Use version history. Because one accidental delete can throw your whole ops off track.

And don’t keep it private. If you have a helper, VA, packer — give them access and make updates non-negotiable. Let them own their side of the workflow.

This simple Google Sheet, when set up right, replaces thousands in inventory software — at least till you hit 100+ orders a week. Don’t underestimate it.

Treat this sheet like your control center. Because it is the control center for Inventory Management for Indian Dropshippers.

3. Set Low-Stock Alerts (Your Backup Brain)

Running ads? Busy with influencer collab? Forgot to check stock? Boom — you just sold something that’s not even in stock.

That’s why you need alerts. Shopify has it. So does WooCommerce. Set it once, and it’ll warn you when things dip. Some tools even let you set reorder thresholds and auto-send email alerts or Slack pings when you hit those numbers. Use it. Let tech do the remembering.

You can also go a step further — install apps that auto-tag low-stock products, notify your VA or team instantly, or even pull up weekly low-stock reports for you to review every Monday.

Your job is to stay focused on scaling and brand — not playing guessing games with backend stock levels. Alerts make that possible.

Low-stock automation is not a “big company” feature anymore. If you’re doing even 10–20 orders/day, it can save you hours of headache each week. It’s the difference between chasing problems and staying two steps ahead of them.

No more guessing. No more “oh crap” moments. If you want to move like a real brand, let systems remind you before your mistakes do. That’s how pros operate in Inventory Management for Indian Dropshippers.

4. Always Have a Reorder Plan (Not Just Hope)

“Chal na, abhi 10 piece toh bacha hai” is not a reorder strategy. That’s panic-mode ops — not how a legit brand runs.

You need to set reorder points. Like this:

- Product sells 30/month

- Takes 10 days to restock

- Reorder when 15 left

Simple math. But it protects you during sale spikes, ad pushes, courier drama, or even when your supplier ghosts you for a week.

Set your minimum stock level and reorder threshold — write it down. Make it part of your weekly ops SOP. If a product drops below 15 units, it should automatically be flagged.

You can also use inventory apps or even Google Sheet scripts to color-code thresholds or auto-email your supplier.

Bonus tip for Inventory Management for Indian Dropshippers: always keep a ‘reorder buffer’ — like 10 extra units for hot sellers — just in case your courier delays by a few days or ads spike faster than expected.

This is how real operators run their backend. They don’t “hope” stock lasts — they calculate and plan like grown brands.

If your restock takes time and you don’t plan ahead — you’re basically gambling with your own money. And in dropshipping, gambling equals refunds, bad reviews, and burned ad budgets.

Build a system once. Sleep better every night after that.

5. Weekly Inventory Check (Not Daily, Not Random)

Don’t waste energy checking stock every single day — that’s burnout.

Pick one day a week. Friday or Monday works best. Do a 30-min sweep:

- Count your top 10 SKUs

- Check what’s almost out

- Flag what needs reordering

Build the habit. Even when you grow, this becomes a team SOP. But for now — you gotta run this show like a tight ship.

6. Use Tools When Spreadsheets Start Breaking

Once you’re doing 100+ orders/week, that Google Sheet will become chaos. Wrong cells, missed rows, double entries — you’ll lose track.

That’s when you move to proper inventory software:

- Zoho Inventory (India-based, GST-friendly)

- EasyEcom / Unicommerce (for serious marketplace guys)

- Shopify + Stocky / Sorted (plug and play for D2C)

They’ll update stock in real-time, track returns, auto-generate reports, and keep your ops tight.

No more “arre bhai check kar le na” drama. Just clarity.

7. Plan Around Indian Seasonality (And Not Last Minute)

In India, you don’t need Christmas to spike. You’ve got:

- Diwali

- Navratri

- Eid

- Rakhi

- Shaadi season

If you don’t prep at least 3 weeks ahead — you’re not scaling, you’re scrambling.

Look at your last 3 months’ orders. Talk to your supplier about lead times. And for first-timers? Note it all down. It’ll save your neck next year.

8. Don’t Overbuy to Feel Safe

“Let’s order 500 pieces — just to be safe.” That’s how broke stores are born.

Smart brands don’t hoard — they rotate. Here’s the rule:

- If it’s scaling, order more

- If it’s not moving, don’t hoard hope

- If you’re unsure, test in smaller batches

Money stuck in dead inventory = cash you can’t use on ads, content, or next winning product.

Keep it lean, Keep it smart that is the mantra for Inventory Management for Indian Dropshippers.

9. How to Handle Inventory When You’re Scaling Fast

Once your ads start hitting and your orders go from 20/day to 100+/day, that’s when most dropshippers crumble. Why? Because their backend can’t keep up with the frontend heat.

Here’s how to avoid the mess:

✅ Switch from solo to team mode

If you’re still doing everything yourself — stop. Hire a packer, even part-time. Train them to handle inventory the way you want. Show them the sheet. Walk them through SKUs. Make them accountable.

✅ Outsource your fulfillment (if needed)

If you’re spending more time packing than building, you’re done scaling. Use fulfillment partners like Shiprocket Fulfillment, Wefulfil, or even a local 3PL. Send them 200–500 units, and let them handle the pick-pack-ship game.

✅ Automate reorder workflows

Don’t wait till stock hits zero. Use automation tools that alert you when product stock dips below a certain number. Many platforms let you auto-generate purchase orders, or at least remind you weekly. Set it and forget it.

✅ Set inventory KPIs

Treat your inventory like a performance metric. Track:

- Sell-through rate (what’s actually moving)

- Dead stock count (what’s been sitting for 60+ days)

- Stock accuracy vs sheet

Have a dashboard. Or at least a Notion board. Look at it weekly.

✅ Forecast like a grown brand

Pull last month’s sales. Use that to project demand for this month. Keep a buffer. Always pad your estimate by 15–20% if you’re running ads. If you don’t forecast, you’re guessing.

Scaling = more orders, more chaos, more customers watching. So you need your backend tighter than ever.

This section alone will separate hustlers from actual operators. Play it smart, not sloppy for Inventory Management for Indian Dropshippers.

Final Word on Inventory Management Basics for Indian Dropshippers

Inventory is not boring backend stuff. It’s your silent business killer — or your secret edge.

Start with sheets. Build good habits. Set reminders. When volume comes in? Shift to tools, scale clean that’s the whole process for Inventory Management for Indian Dropshippers.

Backend needs to be tighter than your frontend. That’s what real brands do.

Need my sheet template, reorder calculator, or app stack? Go to Dropshipping.blog. Built for Indian dropshippers like us — tested in chaos, not in theory.

Let’s stop winging it. Let’s build properly. 💥